Do you remember Andy Griffith, the TV show? Admit it. You're whistling the theme song right now, aren't you? It's catchy and easy to remember, much like the program and the decade it originally aired.

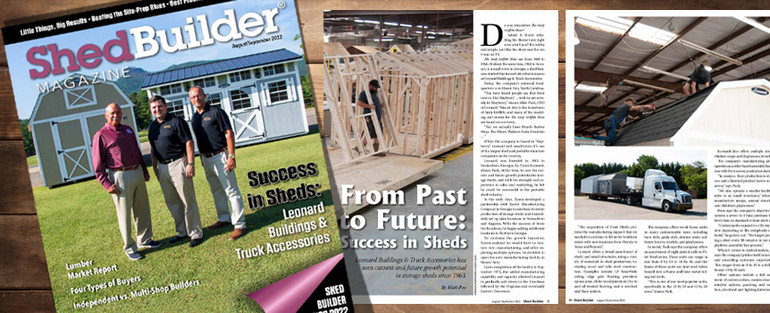

The Andy Griffith Show ran from 1960 to 1968. Leonard Buildings & Truck Accessories, started in a tiny Georgia town around the same period, it began as a shed business that grew into what is now known as Leonard. Today's headquarters is in Mount Airy, North Carolina. "You've probably heard people say their town is 'like Mayberry,'... We're not kidding," says Mike Pack, Leonard's CEO. "Our town, Mount Airy, is the hometown of Andy Griffith, and many of The Andy Griffith Show's modeling and events are based on it. "Yes, we have Floyd's Barbershop, The Diner, and Walkers Soda Fountain...," Pack adds.

While the company is based in “May- berry,” Leonard isn’t small town; it’s one of the largest shed and portable structure companies in the country. In the mid-1960s, he saw storage sheds' present and future growth prospects, and with his sales and marketing skills, he believed he could succeed in the portable shed business.

To elevate his company, which was still in its infancy, Tyson started working with Garret Manufacturing Company in Georgia to acquire its entire output of storage buildings. He began selling them in Swainsboro and Augusta after developing a partnership with Garret Manufacturing Company in Georgia to purchase the whole production. To continue this trajectory, Tyson recognized he'd have to branch out into production before long; thus, he decided to build his factory in Mount Airy after researching many alternatives. After the plant opened in September 1972, Leonard was able to progressively increase its number of stores throughout the Carolinas, Virginias, and eventually Eastern Tennessee as a result of the additional manufacturing capacity.

"The Leonard retail model evolved over the years to include truck covers, truck accessories, and a broad assortment of utility trailers, although the Leonard roots remained in our successful storage shed product segment," Pack says.

By 2015 Leonard had 52 locations, and Tyson made the decision to retire and subsequently transitioned the business to private equity ownership, backed by Kinder-hook Industries, a firm based in New York, which has provided the capital and support necessary to rapidly grow the organization from 52 in 2015 to 75 locations today. That number is even higher since the company acquired Cook Portable Warehouses earlier this year.

“Through a combination of new store growth and the acquisition of existing businesses, Leonard has laid out an aggressive five-year plan to expand our business to over 250 locations by the end of 2025," Pack says. "In just two years, we've gone from 58 to 140 shops. “Portable warehouses are something that was formed by accident, according to John Cook. In February 1984, Cook Sales Inc., the parent firm, was created as a brokerage company specializing in selling railroad abandonment materials in the Southeastern part of the United States. A deal was struck with a sizeable pressure-treated timber firm in Georgia to sell them vast quantities of cross ties, and they were sold to landscape timber suppliers for building supplies.

"A trade was made to exchange a load of railroad cross ties for a similar quantity of pressure-treated timber as part of that relationship," notes Pack. "The plan was to sell the wood at Cook's location in Southern Illinois.

""They'd tried to sell the timber for weeks but with no luck. It was decided to make something out of the wood—and that something was a portable structure! The first building sold quickly, so Cook Portable Warehouses was established as a result."The name, Cook Portable Warehouses, was not chosen by chance. Shortly after constructing several show buildings, Cook spent approximately $100 per month to store his belongings at a self-storage facility. These facilities were formerly known as tiny warehouses. He figured storing his things in one of the display sheds would save money. This waswhen the concept of renting portable storage containers over self-storage units was conceived.

"In the late 1980s, Cook would put up a leased storage building on the customer's site and allow them to purchase it for a portion of each rental payment," says Pack. "This was not only the inception of Cook Portable Warehouses; it also marked the beginning of rent-to-own in the portable construction sector, with almost every major portable construction firm currently providing some sort of rent-to-own option for their goods." Cook also provides 83 independent retailers with distribution services via a wholesale approach.

The Leonard/Cook firm owns seven large-scale manufacturing sites in six states. Each of these facilities utilizes a variety of manufacturing processes. "By 2022, the combined Leonard/Cook company will have manufactured over 2.5 million square feet of sheds/storage solutions, and it is rapidly expanding," Pack added. "We currently have a foundation in place for success on a national vs. regional basis thanks to our year-end advancements in production capabilities, management team, and infrastructure creation. "With the acquisition of Cook Sheds, we now have manufacturing support to continue opening new sites in the Southern United States from Florida to Texas and beyond.

"Leonard specializes in building sheds and other small structures from various materials, including wood and tube steel construction. LP SmartSide siding, edge gold flooring, premium spruce pine, white wood premium 2x4s, and all treated flooring are just a few examples of the unique elements available.

The firm provides wood frame units in various customizable measurements, including barn-style, gable-style, dormer units, salt boxes, lean-to models, and playhouses. Pack says the company offers eight metal units it refers to as its Pilot Steel series. These can range in size from 8 by 10 to 14 by 50, and their frames are made out of bent steel tubes brazed together with metal siding and roofs. "This is one of our most popular packages, especially in the 12 by 20 and 12 by 24 sizes," explains Pack.

Leonard also sells chicken coops and dog houses/structures in various sizes. The firm's production process is a roller-based assembly line with five to seven production stations. "In essence, station one is the flooring, and station seven is the finished product," Pack adds.

"We also have a smaller plant we refer to as 'small structures,'" Pack continues, "where we create ramps, animalstructures, and children's playhouses." Leonard's objective is to deliver goods within seven to fourteen days on standard or store stock units."Custom units expand to 30 daysbased on the complexity of the build," he adds. In Pack's roller platform assembly line method, we aim to produce a shed every 30 minutes.A full range of custom colors, door and window choices, paneling and insulation, electrical and lighting (interior and exterior), andsiding alternatives include LP SmartSide siding, vinyl siding, and Hardie-Plank. "Our metal and vinyl siding options are trendy," Pack says.Panel saws, framing tables, razor multi-cut saws, double-cut saws, cut-off saws, steel tube bender, brazing tables, and general air tools are just a few of the means employed in constructing its structures. The firm owns a truck fleet as well as flatbed and container trucks.Leonard's material availability and ever-fluctuating costs have been difficult to manage over the past 18 months, as many producers have discovered. Pack says,

"We've kept production running smoothly by leveraging our network of suppliers and hard work, ingenuity, and a pinch of creativity."

"We are fortunate to have a diligent, talented, and adaptable team that has been very flexible and helpful as we continue our growth plan," Pack adds.

"We strive to recall what we refer to as the 'moment of truth,'" says Pack. That moment is when a customer's yard is fully completed with a shed. When the client is pleased with their shed and, more significantly, impressed by the quality of construction/build, atthat moment, we either win or lose.

"We are dedicated to creating an excellent experience for our clients." Pack states that for Leonard/Cook, quality is of the utmost importance to them."We are confident in delivering an exceptionally high-quality unit from our productioncenters; in fact, our plant managers personally inspect the completed product," he adds.

"When a customer service concern arises, our in-house repair staff responds swiftly to remedy or address the problem."Those are small hometown principles even Andy Griffith would be able to embrace.